There are many different types of bulk bags, from FIBCs to ventilated ones. This article will discuss the advantages and disadvantages of each type, as well as the differences between them. If you’re considering using one of these bags for your business, you should understand the differences between Type C and Type B before making a decision. The differences between these types of bulk bags can make them the best choice for certain situations. Manyan Inc. is one of the biggest and most popular brands that make these bulk bags and distribute them in North America. You can always talk to them to get bulk bags for your commercial use.

Ventilated bulk bags

Table of Contents

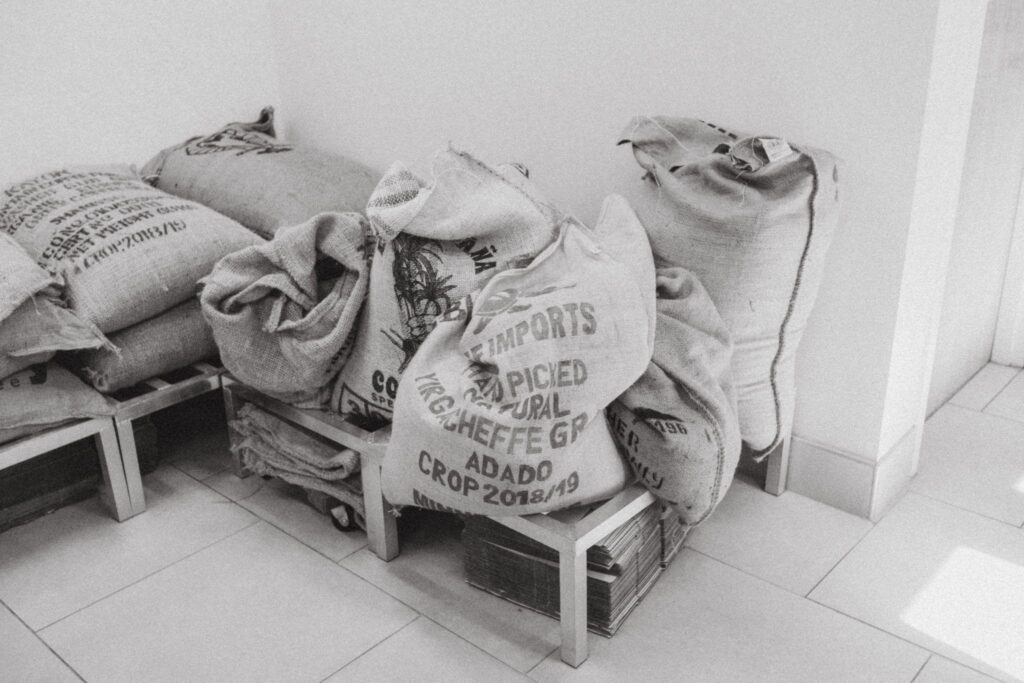

Ventilated bulk bags are breathable bags made of special fabric. They are used in industries that handle dry solid goods, especially in the chemical, pharmaceutical, and food industries. As they are breathable, ventilated bags are an ideal choice for the storage and transportation of these materials. Besides, they can be easily customized according to the customer’s specific requirements. Listed below are some of the most popular uses of ventilated big bags.

The agricultural sector in the Asia Pacific is expected to witness substantial growth, driving the global ventilated bulk bags market. China and India are the leading producers of vegetables and fruits, which are predicted to drive market growth over the coming years. The European market is also expected to exhibit moderate growth during the assessment period. Several key players operating in the ventilated bulk bags market are LC Packaging, Carpo Industries, JumboSack Corporation, Cliffe Packaging Ltd., and Global-Pak Inc.

Ventilated big bags are highly protective and breathable, featuring a mesh fabric and special air stripes for improved ventilation. They feature a high safety factor and are made from heavy-duty polypropylene. They are also designed with filling mechanisms, duffle top/bottom, and a variety of colors. They are a cost-effective bulk packaging solution for many applications. The main advantages of ventilated bulk bags are its high airflow capacity, low moisture content, and ease of use.

Type C FIBCs

FIBCs are bulk containers used for hazardous materials. Type C FIBCs are made from non-conductive fabrics interwoven with conductive threads. They are designed to help ground electrostatic charges and are often used in explosive atmospheres. To use Type C FIBCs, make sure the container is grounded. Otherwise, you may cause dangerous static discharge hazards. However, if you are using a conductive FIBC, you will need to take special precautions to ensure it is grounded.

In environments with combustible dust, a Type B FIBC is recommended. Its low breakdown voltage will help protect the contents of the container from highly energetic brush discharges. However, Type B FIBCs cannot be deemed to be antistatic as they lack the mechanism to dispel static electricity. They should also not contain flammable solvents or gases. This may lead to explosions. If you’re unsure about the safety of an FIBC, it’s best to contact the manufacturer or ask for recommendations.

In some industrial settings, handling of bulk materials is done in a bulk form. In a Type C FIBC, all conductive materials are grounded. This is because flammable materials often contain materials that have high levels of static electricity. Moreover, the conductive materials are electrically bonded and include ultra-molecular carbon additives to further dissipate static charges. FIBC Type C and D bulk bags must meet this electrostatic requirement and should be used in such environments.

Type B FIBCs

The UL Class II Standard covers a wide range of flammable liquids and gases. Type B FIBCs are ideal for use in environments where explosive dusts are a danger. These containers are made of non-conductive materials and feature an anti-static additive in the plastic or coating. Because they are made of non-conductive materials, they can reliably prevent the ignition of combustible dust.

However, there are some critical characteristics to be aware of before purchasing a flammable liquid container. First, you must determine whether the product is flammable. Secondly, you must check whether the type of liquid you’re considering is compatible with the type of atmosphere in which the flammable liquid will be transported. This is especially true if the liquid is flammable. Lastly, you need to determine what type of liner the FIBC will use.

Second, Type B FIBCs have high-quality panels to prevent brush discharge and sparks. This helps avoid potential electrical hazards associated with handling flammable materials in dusty areas. They are also designed for use in environments where they may be subjected to high amounts of static electricity. In short, Type B FIBCs provide full protection from electrical hazards. In contrast, Type A FIBCs are not antistatic.